Automated Quaywall Design

Automated Quaywall Design

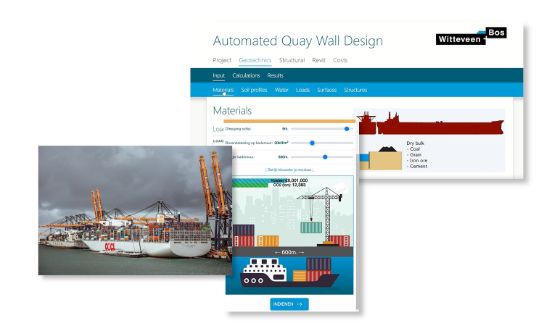

When constructing a quay wall, specialists are always required. After completing their task, they pass their data on to the next person in the design process. It is a time-consuming way of working and brings with it the risk of unclear communication and errors. Automated Quaywall Design (AQD) solves this and gives port managers more control over possible options.

Quay wall quick wins are easily visible

Thanks to AQD, port managers are able to quickly understand the various aspects of a design and the consequences of adjustments. If a port is intended for a certain type of ship (or a certain size), then a particular type of quay wall will be required. AQD helps Witteveen+Bos engineers show what investments would be needed to accommodate other types or sizes.

Alternatively, it is also possible to demonstrate which savings would be possible by lowering ambitions. Quick wins in a design can quickly be identified with AQD. This saves time, but it also quickly provides insight regarding choices of materials and CO2 emissions. In short, AQD makes informed choices possible.

What if...?

It is possibly the most frequently asked question during the design phase: ‘What if?’. ‘What if we replace material A with material B, and what if we raise the quay wall by ten cm?’. With AQD, the answers are very quickly available. In the past, engineers had to first go back to their drawing boards and recalculate. After a few weeks, they world return with modified proposals. With AQD, the variants and their consequences are immediately visible. The tool supports the engineers in providing balanced advice and discussing possible variants with the client.

AQD brings all the disciplines involved in designing a quay wall together. This is made possible by automating every step in the process. As a result, a quay wall can be drafted and calculated with the proverbial press of a button.

Why Automated Quaywall Design?

Design quickly

In the past, it took engineers weeks to provide new proposals. With AQD, the variants and their consequences are immediately available.

More insight

The tool gives port managers clear insight into the various aspects of a design and the consequences of adjustments. This makes it possible to make informed choices.

Brings all involved disciplines together

Thanks to the tool, all the various disciplines can be involved in the design.

Want to know more?

Elmo uses parametric design and innovation to provide sustainable and climate-proof solutions.