Recovering surplus heat in the Port of Rotterdam

Recovering surplus heat in the Port of Rotterdam

Over half of the energy in the Netherlands is used for heating. Of this, 47% is used to heat homes and businesses. Almost all of this heat currently comes from fossil sources, especially natural gas. By 2050 it is the intention that (industries in) Europe should be climate neutral. With the WarmtelinQ project, the largest port and industrial complex in Europe plays an important role in achieving this objective.

Gasunie's WarmtelinQ project is a unique and large-scale heat-exchange project involving the world's first open heat transport pipeline. Witteveen+Bos is proud to have been selected as the official engineering partner for this project.

Gigantic central heating system

WarmtelinQ was initiated by Gasunie with the aim of using residual heat from the Port of Rotterdam to heat homes and businesses in South Holland via an underground pipeline. In time, approximately 120,000 homes will be able to use residual and renewable heat with WarmtelinQ. Compared with traditional gas-fired central heating boilers, this will result in a CO2 reduction of 60%. The transport pipeline will also create opportunities for connecting new local heat networks in the other municipalities along the route and opportunities for providing access to other local sustainable sources of heat. The integral design takes into account the possibility of the heat network ultimately serving the entire province. On this scale, heat has never been used before.

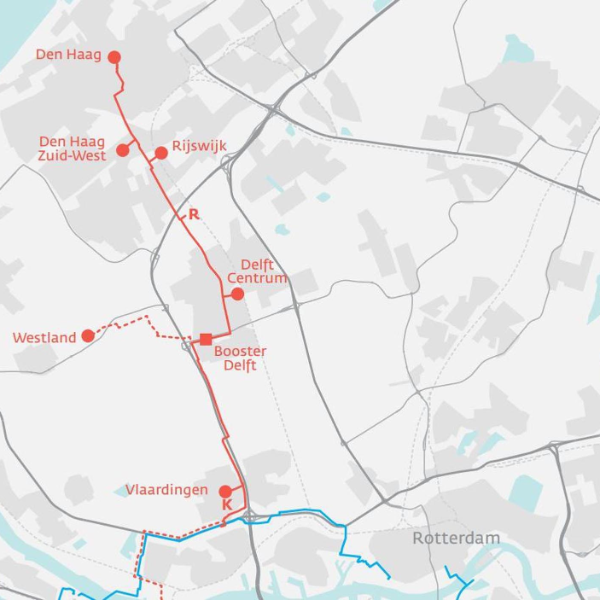

WarmtelinQ consists of a supply and return pipeline. The supply pipe carries the hot water to the heat distribution networks. The return pipe brings the (cooled) water back to the heat source from which it originated. There it is reheated and returns to the supply pipe. The route is 23 kilometres long and runs from the port of Rotterdam via Vlaardingen to The Hague. It can be seen as a gigantic central heating system. At the moment, it is being investigated whether the pipeline can be extended to Leiden and whether various branches for the Westland and Oostland can be constructed to bring the residual heat to greenhouses in the area.

The Design

We have mapped out the disconnection of industrial residual heat in the port of Rotterdam. In coordination with the industries in the area we determined the amount and temperature of available residual heat. Based on this we made initial designs for the required heat transfer stations and, together with our partner Rotterdam Engineering, we have made the designs for the pipeline route to the "backbone" of the heat network. These designs have been coordinated with the relevant industries and, based on this, our experts have prepared an estimate of the investment costs per location. The designs have also been used by WarmtelinQ to draw up the overall system design.

Delft pumping station

Because the water has to be transported over a long distance, a pumping station will be built halfway along the route in Delft to maintain sufficient pressure in the pipes. This pumping station is the driving force for pumping the water around in the entire system. There will be huge pumps, with a volume flow of more than 2,000 tonnes per hour and a pressure of more than 20 bars. The pumps are driven by frequency-controlled 6 kV motors with an installed capacity of approximately 2MW per pump.

Witteveen+Bos' experts prepared the Basic Design and the Detailed Design for the pumping station. The Detailed Design is worked out to the Implementation Design level and sometimes this goes even further: so-called isometrics are drawn up showing every weld and flange in detail and the order specifications for pipe parts and fittings are drawn up, so that these parts can be ordered by Gasunie without further elaboration. Since this is the first (large) above-ground object to go through such a design process, together with WarmtelinQ, we have made a large number of technical choices which will also be applied to other objects in the project. Fitting the pumping station into the limited space available was a particular challenge, especially because of the required piping. The pipes have an outside diameter of 700 mm and a special system to detect leaks quickly. Because considerable temperature differences have to be taken into account, several expansion loops have been included in the system. To this end, we carried out detailed pipeline stress calculations.

Where are we now?

Preparatory work has started on the section from Vlaardingen to The Hague. It is estimated that the construction work will start this summer (2022) and that the laying of the entire pipeline will take 16-24 months. In the future, other sustainable heat sources will be connected to WarmtelinQ, provided that they meet the technical requirements. For example, heat from water, from the ground or from other sustainable sources.

More information?