SEIMS

SEIMS

Designing process plants is complex. These projects are often large where many different disciplines come together, such as mechanical, electrical, process automation and process technology. This involves an enormous amount of data. Previously, all this data was kept in all kinds of different Excel files. Changes to the data then had to be made manually in all versions and files. This is a time-consuming and error-prone job. This calls for structured data handling. SEIMS offers help.

SEIMS

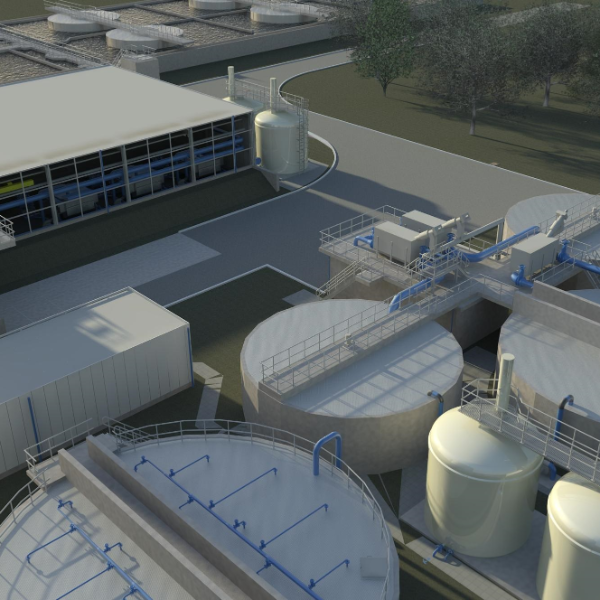

SEIMS (Smart Engineering Information Management System) is a common data environment (CDE). This system is used by Witteveen+Bos within multidisciplinary engineering projects, for example for the design of a water treatment plant. SEIMS supports the work process within these projects. Several users can work on the same project simultaneously and view each other's changes. SEIMS helps with optimal version management, so that it is always traceable by whom, what and when changes are made. In addition, SEIMS allows users to add comments and warnings to the data.

How SEIMS works

With SEIMS, all data is stored in a standardised format in one place in the cloud. Because SEIMS links data, documentation management works faster and is less likely to contain errors. This improves the quality of the projects.

Working together in SEIMS: AutoCAD Plant 3D integration

A big advantage of SEIMS is that it is integrated with AutoCAD Plant 3D. Data is automatically synchronised between the two systems. This allows users to work simultaneously in the different systems. The automatic synchronisation provides assurance of completeness and consistency between both systems. Time-consuming manual checks are therefore no longer necessary.

Why SEIMS?

Quality

Because all data can be found in one place, fewer mistakes are made. This increases the quality of our projects.

Speed

Because all datasets are online in the cloud, they are easier to find and changes can be made faster. As a result, projects are delivered earlier.

Working together

All stakeholders within a project can work in SEIMS. It is also possible to post comments and questions, our engineers can respond to these. This improves the work process.

Want to know more?

As a process automation engineer, Wouter aims to make engineers' work as smart and fun as possible. To this end, he develops digital tooling that helps automate work.