Nature-based clean water production

Nature-based clean water production

Many production sites of drinking water companies are located close to nature reserves. This offers opportunities to integrate biodiversity (flora and fauna) not only into the design of new production facilities, but also into the expansion/renovation of existing sites, as was the case in Ouddorp where we collaborated with Buro Kade to design a water softening facility for Evides. We also made a detailed design of the process installation that took into account the limited space in the building.

The production site is located in the Middel- en Oostduinen nature reserve on the delta island of Goeree-Overflakkee. This dune landscape has been an important source of drinking water for the island since 1934. The company extracts water from the Haringvliet, purifies it and then allows it to infiltrate the dunes through canals and lakes. The water is then further purified by organisms in the soil. According to Evides, water extraction in the past caused disturbance to the natural environment of the dunes. For this reason, the company modified its water production in the 1990s. The impact of drinking water extraction on the natural environment has been reduced, resulting in an increase in biodiversity in the Middel- en Oostduinen and a return of various rare species of plants and animals.

An extra step forwards

The importance of local flora and fauna was also reflected in the design of the new water softening facility. Buro Kade was largely responsible for the exterior design, with Witteveen+Bos contributing its ecological expertise. For this specific project, we employed, among other things, our sustainable design principles (SDPs), in particular the multifunctional design SDP and, to a lesser extent, the nature-based design SDP. Multifunctional design was applied to ensure the design and surrounding area are more nature-inclusive. This means that we went a step further than what is stipulated by the Nature Conservation Act.

Opportunities for flora and fauna

To begin with, we used distribution data to map protected and non-protected plant and animal species. In doing so, we assessed whether the specific design – in this case a water softening facility – can have negative but also positive effects on certain local flora and fauna.

We then made a selection of plant and animal species which we could have the greatest impact on with the design and in the environment. In the case of Ouddorp, we selected, among other things, the wheatear and the bat.

Bat bunker

Additional nesting sites/shelters were created, such as nesting boxes for tawny owls, wheatears and bats, and accessible wall cavities and a special bunker for bats. As far as flora is concerned, we incorporated a sedum-dune roof, which also has a beneficial insulating effect (nature-based design). Finally, we recommended environmental interventions, such as creating a wet dune valley and committing to further development of a dune lake to improve water quality and encourage lakeside vegetation.

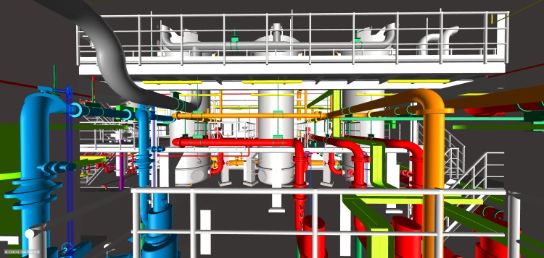

3D model

Incorporating the process installation in the water softening facility proved quite a challenge, as the dimensions of the building were relatively restricted, given the amount of space available on the site and the client’s aesthetic demands. For this reason, we used a 3D model in which the process installation and pipelines were drawn up in detail. Ensuring accessibility for the staff (for maintenance, repairs and replacement) was a prerequisite in the design.

Customisation

The drinking water is pretreated in the softening facility in three steps: aeration, softening and the removal of arsenic. These process steps are implemented on the basis of conventional technologies. However, that does not mean to say that it is simply a case of utilising tried and tested technologies. Every drinking water installation requires customisation, such as the right process-technical dimensioning, integration into the available space and connecting to the existing purification system. In the case of the existing purification system, we have separated the water supply of the deep and shallow wells in the softening facility. This is because deep wells contain purer water and require a less intensive treatment process.

Conversion plan

The construction poses its own challenge, given that drinking water production cannot be shut down while the work is being carried out. For this reason, we have drawn up a detailed conversion plan with the client. In this, the original pipeline to the main building will be disconnected only at the last moment, at which time the pipeline from the softening building will take over the work. The construction of the softening facility will be started in the course of 2023.

More information?