Heating transition in Leiden powered by waste heat from Rotterdam

Heating transition in Leiden powered by waste heat from Rotterdam

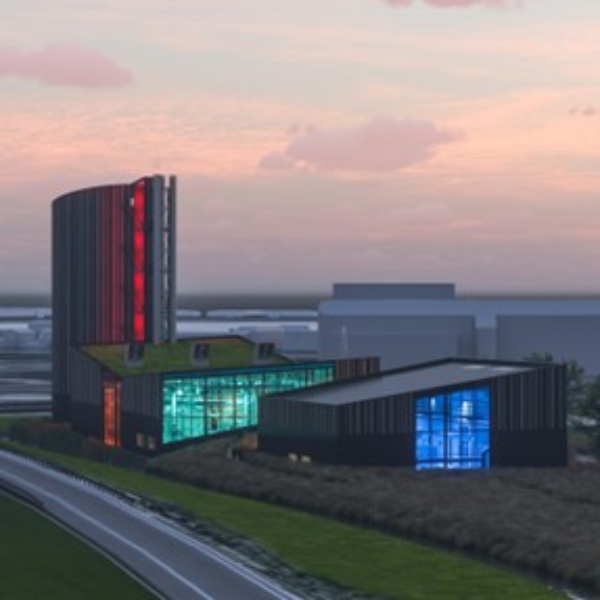

The city of Leiden aims to make its heat network sustainable. At present, a fossil power station supplies heat to the Leiden heat network. The ambition is to use waste heat from the port of Rotterdam as a more sustainable energy source. To achieve this, a new plant to receive, store and distribute heat must be built in the city. Witteveen+Bos was commissioned by Vattenfall to design this plant – Warmtecentrale A44 – with security of supply, sustainability and safety prioritised.

The municipality of Leiden aims to phase out natural gas in all districts by 2050. This means homes and buildings will no longer be heated with natural gas. The municipality says there are many steps to be taken before this goal can be achieved.

One of these steps is the use of waste heat from energy-intensive industries, such as chemicals and petrochemicals, and waste incineration plants. Companies in the port of Rotterdam produce more than enough waste heat, which is currently discharged into the river Meuse or into the atmosphere from cooling towers.

WarmtelinQ: heat highway for South Holland

The WarmtelinQ project involves the construction of a heat pipeline network between the port of Rotterdam and nearby towns and cities in the province of South Holland, including Leiden. Before it can be used, this waste heat must be injected into the existing Leiden heat network, which is operated by Vattenfall.

Warmtecentrale A44, named after the adjacent highway, will receive and store the waste heat and feed it into the local heat network. The waste heat will be used to serve the base load, with extra heat supplied at peak moments by heat buffers/storage and natural gas boilers.

Huge buffer tank

Warmtecentrale A44 includes two large plate heat exchangers, which transfer the waste heat and act as a physical barrier. Three gas-fired boilers with a capacity of more than 33 MWth each (comparable to the power of 20,000 kettles) fulfil peak demand and serve as a back-up. In the future, the boilers can be converted to run on hydrogen or replaced with electric boilers. A 30-metre-high Heat Accumulation Tank (HAT) buffers the waste heat and maintains the correct pressure in the heat network, even if a leak occurs.

Ideal heat mix

Witteveen+Bos produced the final design for the heat plant. It was a challenge to fit the processing equipment into the existing building design, while leaving sufficient space for maintenance and the potential replacement of the gas-fired boilers with e-boilers or hydrogen boilers. Security of supply was an important parameter in the process design, and is guaranteed by the storage/buffer capacity, the ability to deploy gas boilers and a back-up electricity supply. Flexibility is essential to deal with outages and maintenance etc.

The expectation is that Warmtecentrale A44 will be up and running in 2027. It will supply heat to around 10,000 households and 200 bulk consumers.

Photo credits: Moen & van Oosten architekten/visualisatie: CIIID

More information?