Treatment concept demonstrated at LIFE Water Factory in Wilp

Treatment concept demonstrated at LIFE Water Factory in Wilp

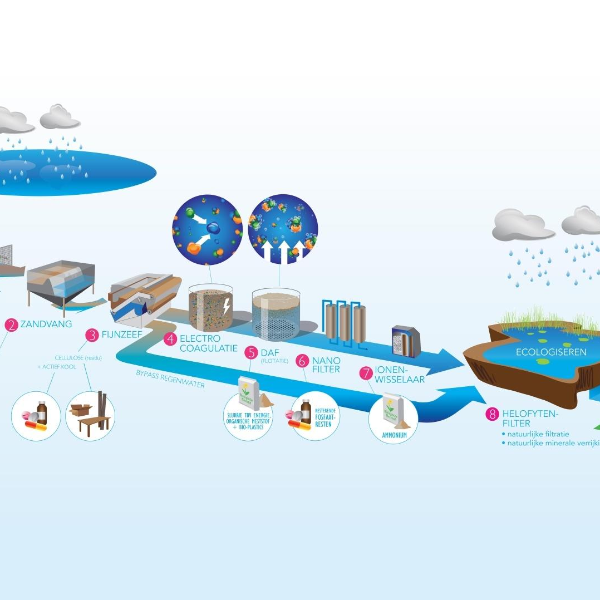

Very clean water and future-proof water treatment. The Vallei en Veluwe water authority and the Dutch Water Refinery, comprising Royal HaskoningDHV and Witteveen+Bos, have demonstrated the operation of the new treatment concept at the future LIFE Water Factory in Wilp in a pilot setup. Rather than treating the wastewater biologically, raw materials are extracted using a separation process that does not release greenhouse gases. The clean water will be used to supply the Twellose brook. This is in line with the water authority's vision and presents opportunities for the future, for example in the fight against local drought.

‘The fact that the concept works gives us confidence for the future,’ says Tanja Klip-Martin, chair of the Vallei en Veluwe water authority. ‘It’s a major step in the transition to becoming a fully circular water authority by 2050. Extracting sustainable energy and raw materials is now inextricably linked to water management in our region. Translating the pilot setup into a fully functioning circular water factory will require further optimisation and development. We will continue to work on this in collaboration with our partners, market players and research institutes.’

Pilot setup at LIFE Water Factory in Wilp

A pilot setup with a unique and innovative treatment concept was tested at the Terwolde wastewater treatment plant between May 2019 and June 2020. The trial generated valuable information about the quality of the purified water, energy consumption, costs, system reliability and the volume of residual flows. The results showed that the physical-chemical separation concept produces high-quality purified water, removes most pharmaceutical residues and allows raw materials such as cellulose and nitrogen to be extracted from the residual flows. This treatment process also eliminates the need for bacteria, which means that no greenhouse gases are emitted in the process. Although energy consumption and operating costs are higher than for conventional treatment, this is within the limits set by the water authority.

Optimisation and research

Areas for improvement were also identified. The pilot showed that we can remove residual flows from the process, but more research is needed to find ways of concentrating this flow and breaking it down further into individual substances. The next phase will also look at how costs can be reduced.

Final design to be built in phases

The next step is to translate the results into a final design for the water factory, which will then be built in phases. This way, the volume of wastewater to be treated can be gradually increased from 2.5 to 50 and eventually to 150 m3 per hour. This approach will also provide an opportunity to further optimise the treatment concept during implementation.

In collaboration with partners

Every day, we work with our partners to find better and smarter ways of doing things. For this project, the water authority is working closely with the Dutch Water Refinery (Witteveen+Bos and Royal HaskoningDHV), the Foundation for Applied Water Research (STOWA), Aquaminerals, the municipality of Voorst, Attero and Schoneveld Breeding. The project is financially supported by the European Union's LIFE programme.