Co-engineering on the renovation and PACAS system project at WWTP Oijen

Co-engineering on the renovation and PACAS system project at WWTP Oijen

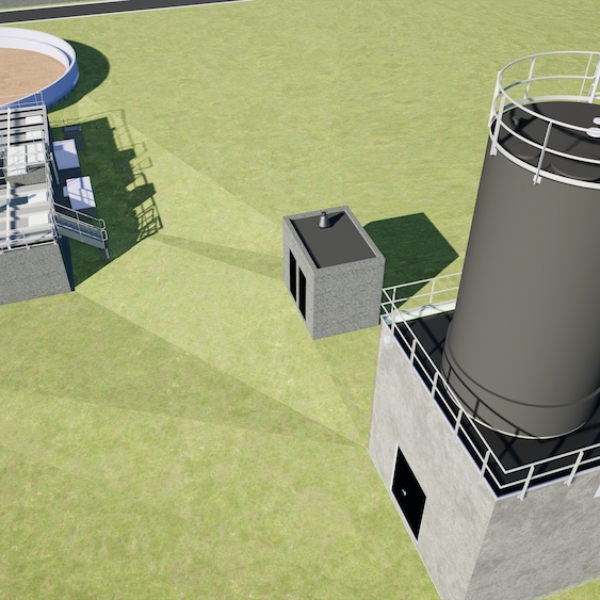

The Aa en Maas water authority has enlisted the help of Witteveen+Bos for the renovation of the WWTP in Oijen. Witteveen+Bos produced the final design and drew up the specifications for the tenders. To remove pharmaceutical residues and other micro-contaminants, the water authority opted to install a PACAS system. For these major renovation works, a special collaborative approach was chosen in the form of co-engineering.

Renovating together

The wastewater treatment plant in Oijen was built in 1975 and will undergo an almost complete overhaul in the coming years. Once the works are complete, wastewater will leave the treatment plant even cleaner than before. Employees from the Aa en Maas water authority and Witteveen+Bos have formed a number of multidisciplinary teams that work closely together, ensuring that the various aspects of the design are addressed holistically. The advantage of this is that issues such as maintainability and business operations then feature more prominently in the design process. Mechanical engineer Wouter Nijboer of Witteveen+Bos: ‘Engineering together opens up new insights and helps you to garner support for complex solutions.’

A new step in the treatment process

A key part of the renovation process is the development of an additional step to also remove pharmaceutical residues and other micro-contaminants. A full-scale PACAS system will be built for this purpose in 2022. The renovation works and the installation of the PACAS system will improve the treatment process to such an extent that it will have a positive impact on the quality of the surface water and thereby on the ecology of this water system. This will be monitored intensively in the coming years through an extensive research programme. Karin Bertens Zorzano, wastewater technician at the Aa en Maas water authority: ‘As a technician, I think it’s fantastic that we’re going to tackle removal of pharmaceutical residues and contribute to a better environment. I’m very proud of this step.’

What is PACAS?

PACAS stands for Powdered Activated Carbon in Activated Sludge. Powdered coal has a very fine structure and a large surface area to which pharmaceutical residues can bind and be removed from the water.

Why PACAS?

After use, some pharmaceutical residues end up in the surface water through the sewage system. As these substances pose a risk to the water environment, water authorities – including the Aa en Maas water authority – have started to devote more attention to pharmaceutical residues in recent years. For the Aa en Maas water authority, this move represents a significant step towards improving the quality of surface water. Protecting the ecology and the Meuse as a source of drinking water is particularly important here. Although some of the micro-contaminants are removed by the existing biological treatment process, it doesn’t go far enough. An additional step in the treatment process is therefore required to improve the removal level.

Co-engineering the PACAS system

Several engineering subgroups also collaborated on the design of the PACAS system. For example, the mechanical engineers worked closely with the management on issues such as maintainability and business operations, and safety specialists from both sides looked at process safety.

More information?